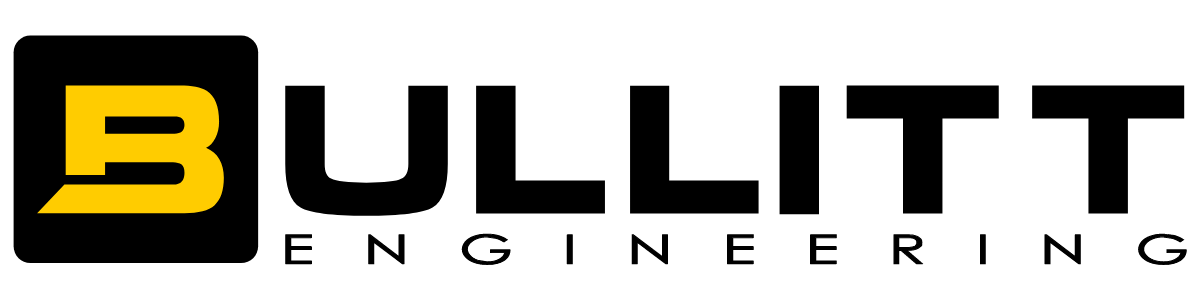

Cooperative robots (cobots): How do they work together with humans?

With the development of industrial automation, cooperative robots (cobots) are playing an increasingly important role in manufacturing processes. Unlike traditional industrial robots that operate in isolated areas, cobots are designed to work side by side with humans, offering a high degree of safety, flexibility and efficiency. This article will examine the principles of cobots, their advantages and applications in modern industry.

What are cooperative robots?

Cobots are robots designed to interact directly with humans in a shared work environment. They feature sensors, safety software, and artificial intelligence algorithms that allow them to recognize human presence, adjust their movements, and automatically stop when they encounter an obstacle. Thanks to these features, cobots can safely perform tasks alongside workers without requiring protective enclosures.

Advantages of cobots

- Safety – Equipped with sensors and collision avoidance mechanisms, the cobots automatically slow down or stop when they detect people nearby.

- Easy programming and implementation – Cobots are often set up through intuitive interfaces or through motion demonstration, making them easy to train and adapt to new tasks.

- Flexibility and mobility – They can be quickly reconfigured for different processes, making them ideal for dynamic production lines.

- Improved performance – By combining human dexterity and the intelligence of AI systems, cobots help increase productivity.

- Reducing physical exertion – Cobots perform heavy or repetitive tasks, which reduces the risk of occupational illnesses and injuries to humans.

Applications of cobots in industry

- Assembly operations – Cobots assist workers in assembling products, ensuring precision and speed.

- Packaging and palletizing – They can sort, package, and palletize products, increasing the efficiency of warehouse operations.

- Quality control – Equipped with cameras and sensors, cobots can perform production inspection, identifying defects with high accuracy.

- Welding and material processing – In certain applications, cobots can perform tasks, such as welding, cutting or grinding, that require a high level of precision.

- Logistics and internal transport – Cobots find application in warehouses and production lines, where they automate the movement of components and materials.

The future of cooperative robots

As artificial intelligence and machine learning advances, cobots will become even more intuitive and adaptive. They are expected to expand their capabilities through better sensor technology, advanced algorithms for gesture and voice recognition, and greater autonomy in task management. This will allow enterprises to deploy cobots in even more complex and diverse manufacturing environments.

How does Bullitt Engineering monitor and implement these innovations?

At Bullitt Engineering JSC, we closely monitor the development of cooperative robots and their application in industrial automation. By analyzing best practices and implementing technological solutions, we help businesses adapt to new trends and increase efficiency through automation.

Conclusion

Cobots are changing the way humans interact with robotic systems by offering safety, efficiency, and flexibility. As technology continues to evolve, they will become even more integrated into industrial environments, providing innovative solutions for automation and workflow optimization.