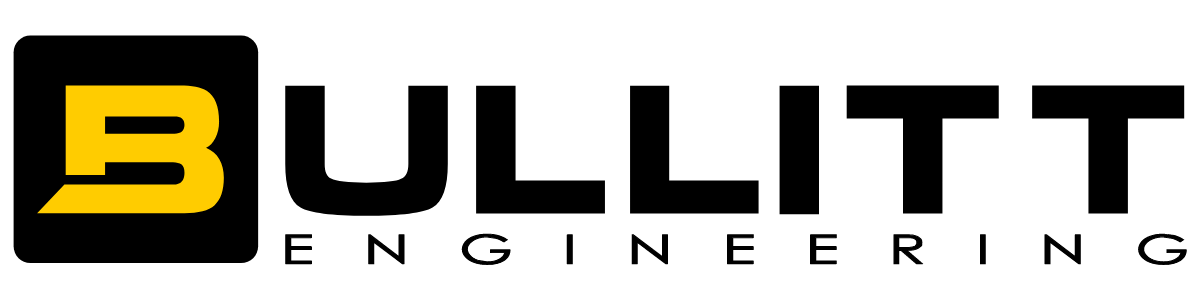

Robots in Industry: How Automation is Shaping the Future of Manufacturing Processes

In modern industry, automation and robotics play a key role in transforming production processes. With increasingly sophisticated technologies, companies are striving to increase the efficiency and quality of their products, and robotic solutions are central to this revolution. But how exactly are robots changing manufacturing, and how are companies like Bullitt Engineering contributing to those changes?

Facilitation of production processes

One of the main benefits of robotics is the facilitation of complex and labor-intensive manufacturing tasks. Robots can perform repeatable operations with consistent accuracy and speed, without the risk of fatigue or human error. This not only increases productivity, but also allows businesses to focus on innovation and optimization. For example, robotic systems such as those developed by Bullitt Engineering enable precision in welding processes while reducing production time.

Improving efficiency and quality

Robots greatly improve efficiency in production lines. They can run without interruption, which means higher productivity and lower labor costs. In addition, thanks to the accuracy of robotic systems, the quality of finished products improves. This results in less waste and less need for rework, which helps reduce costs. Bullitt Engineering is an example of a company that creates customized robotic solutions adapted to the specific needs of customers who strive for high quality and efficiency.

Bullitt Engineering and the role of robotics

Companies like Bullitt Engineering are playing an essential role in the transformation of industrial automation. With years of experience in the design and integration of robotic systems, Bullitt Engineering helps its customers optimize production processes by introducing innovative technologies. These solutions not only increase productivity, but also provide greater flexibility and adaptability of production lines to different products and tasks.

The future of robotics

With the development of artificial intelligence and machine learning, robots will become increasingly intelligent and capable of performing more complex tasks, including adapting processes in real time. This will lead to an even greater level of automation and less need for human intervention in routine operations. Companies like Bullitt Engineering will continue to be a driving force in this evolution, offering innovative and customized solutions for industrial applications.

Robotization and automation are not only the future, but also the present of industrial production. With the help of companies like Bullitt Engineering, manufacturing processes become more efficient, flexible and reliable, enabling businesses to adapt and grow in an increasingly competitive global market.