Integrated solution for MIG/MAG welding with Fanuc CRX-10iA collaborative robot and Fronius TPS 400

In response to the demand for more flexible and safe solutions for industrial automation, the Bullitt Engineering team developed and implemented a robotic MIG/MAG welding system based on the Fanuc CRX-10iA collaborative robot and Fronius TPS 400 welding machine.

The system was created with the real needs of the customer in mind and combines precision, intuitive control and a high degree of personalization.

Main components of the system

- Fanuc CRX-10iA

The collaborative robot (cobot) has a payload of up to 10 kg and a range of 1249 mm. It is distinguished by its exceptional repeatability of ±0.03 mm and installation option in all spatial positions.

The integrated software Arc Tool provides easy configuration of welding parameters. - Fronius TPS 400

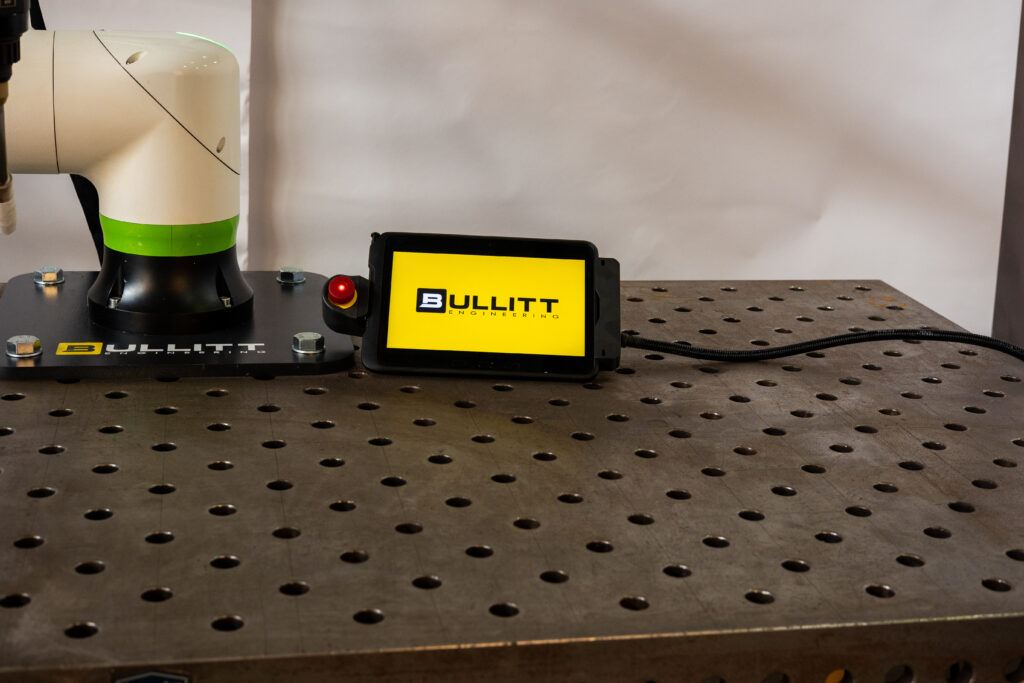

High-performance welding machine, suitable for MIG/MAG processes. Allows fine adjustment of welding parameters, which guarantees high quality of the weld seam. - Intuitive tablet control

The cobot is programmed via a tablet with an easy and accessible interface, which significantly reduces setup and staff training time.

Customized engineering solutions

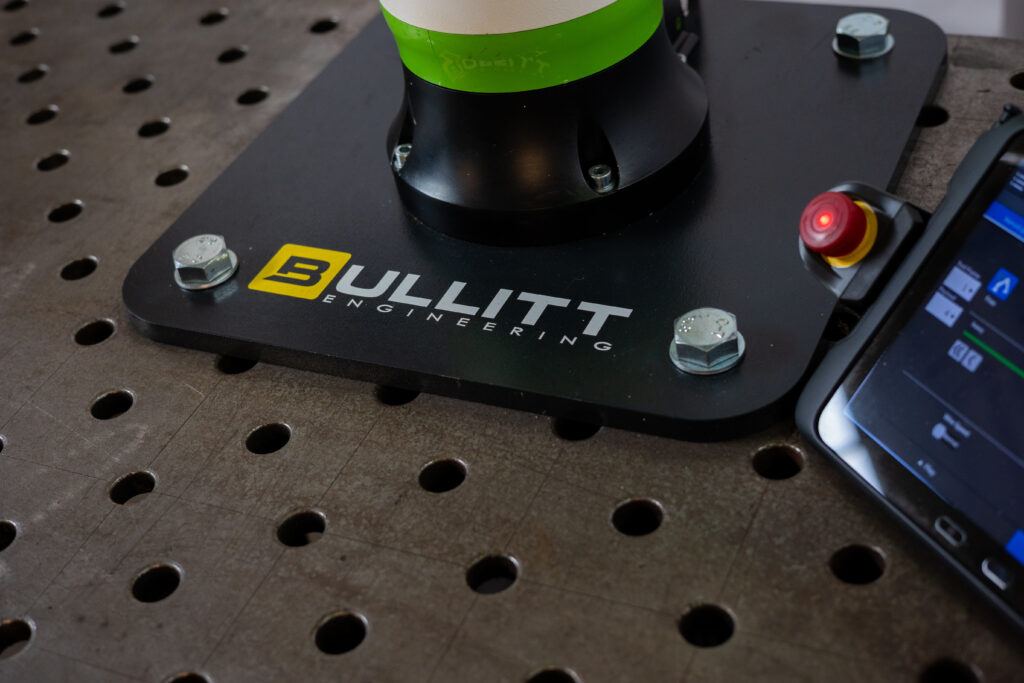

The project includes not only the integration of the main components, but also a number of non-standard engineering developmentsthat improve functionality and ease of use:

- Designed non-standard holder for the welding torch, providing stable and flexible fixation;

- Tools for establishing specific customer details, adapted to the specifics of production;

- Remote control buttons, positioned to facilitate the operator and speed up the work.

Advantages of the solution

- Secure human-robot collaboration, without the need for protective cells;

- Shorter setup time and start-up of a new batch of parts;

- Improved weld quality and repeatability;

- Safer and more ergonomic working environment.

A Look to The Future

The system demonstrates how modern collaborative technologies can be applied in real industrial conditions in Bulgaria – by increasing efficiency, safety and production flexibilitywithout compromising on quality.