The Future of Industrial Robotics: Trends for 2030

Industrial robotics is undergoing a significant transformation, driven by technological innovation, artificial intelligence, and automation. By 2030, robots are expected to be not only smarter and more efficient, but also more accessible and integrated across sectors. In this article, we will explore the key trends that will shape the future of industrial robotics.

Key trends in industrial robotics by 2030

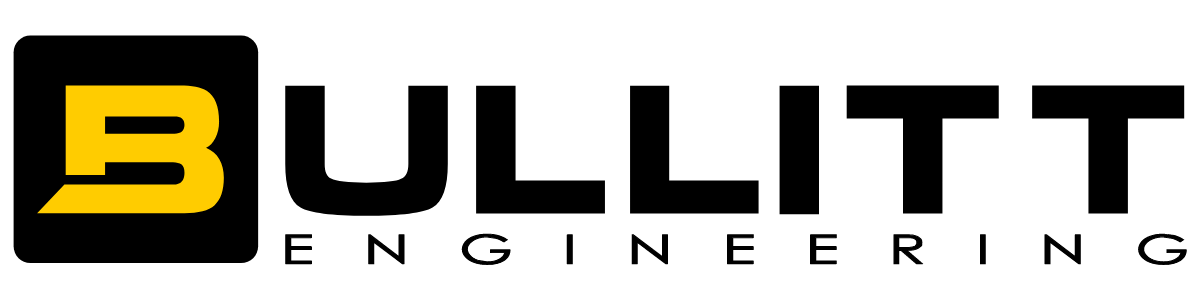

1. Smarter and more autonomous robots

Robots will have advanced AI algorithms that will allow them to adapt to dynamic production environments, make autonomous decisions, and optimize processes in real time. Machine learning and neural networks will make it possible for robotic systems to independently improve their performance.

2. Cooperative work between humans and robots

Cobots will continue to evolve, offering even safer and more intuitive ways to interact with people. The integration of sensors, haptic feedback, and voice control will make collaboration even more effective.

3. Cloud-based robotics

Cloud-connected robots will enable centralized control, big data analytics, and remote monitoring. Industrial enterprises will be able to implement flexible manufacturing systems with less infrastructure costs.

4. Energy efficiency and sustainability

With increasing demands to reduce carbon footprint, industrial robots will be designed with more energy-efficient motors, regenerative braking systems, and integration with renewable energy sources.

5. Modularity and customization

The factories of the future will use modular robotic systems that can be easily adapted to different production tasks. 3D printing will allow the creation of customized robotic components at minimal cost.

6. Increased cybersecurity

As robotic systems become increasingly digitalized and connected, the need for cyber protection will increase. More robust defense mechanisms based on blockchain and AI are expected to be deployed to detect threats in real time.

7. Robotics in non-manufacturing industries

By 2030, industrial robotics will enter new areas such as construction, agriculture, and medicine. Autonomous robots will be used for infrastructure construction, precision farming, and surgical procedures.

How does Bullitt Engineering monitor these trends?

At Bullitt Engineering JSC, we analyze and implement the latest technologies in industrial robotics. We work actively to adapt intelligent solutions that help companies improve their production processes, reduce costs, and increase efficiency through automation.

Conclusion

By 2030, industrial robotics will be more flexible, intelligent and energy-efficient. The development of AI, cloud technologies and modular robotic systems will make automation more accessible to different industries. Companies that invest in innovation and digital transformation will be at the forefront of the industrial revolution of the future.